| EUKRIPTONIT |

Combinations of Ti |

various gold, grey, red |

1800-3000 Hv |

1-6 ym |

600 |

0,2 - 0,4 |

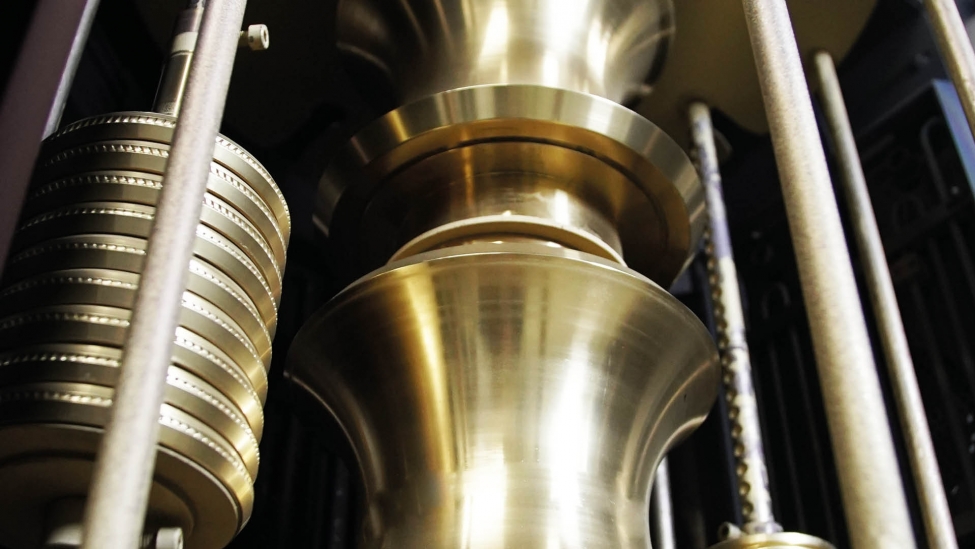

PVD multi-layer multi-process |

tool steel, high speed steel, cermet, tungsten carbide |

good wear resistance, interrupted cut wear resistance, good roughness, good anti-bonding properties, biocompatible |

universal coating for tools, prostheses, medical, milling, turning, shearing and sheet metal processing |

| EUKRIPTOKROM |

Combinations of Cr |

silver/grey |

1500-2500 Hv |

1-8 ym |

850 |

0,2 - 0,4 |

PVD multi-layer multi-process |

tool steel, high speed steel, cermet, tungsten carbide |

excellent polishing properties and low roughness, medium wear resistance, good temperature and oxidation resistance, good toughness, low coating process temperature |

general mechanical components, hot molding, automotive industry, excellent resistance to chemical attack in a particularly aggressive environment, excellent corrosion resistance in the saline environment |

| EUKRIPTAL |

Combinations of Ti, Cr, Al, Si |

various grey, dark purple |

>3500 Hv |

1-8 ym |

1100 |

0,2 - 0,4 |

PVD multi-layer multi-process |

tool steel, high speed steel, cermet, tungsten carbide |

very high oxidation resistance at high temperature, good wear resistance and low friction coefficient, high toughness |

hot molding and die-casting of aluminum, milling, teething and cut interrupted, very versatile on the working of materials such as titanium, stainless steel, nickel alloys, aluminum shearing, dry milling, inserts for drying, inserts for dry turning up to 70hrc. sheet formation, drain bolting |