PHOSPHATE AND NICKEL PLATING

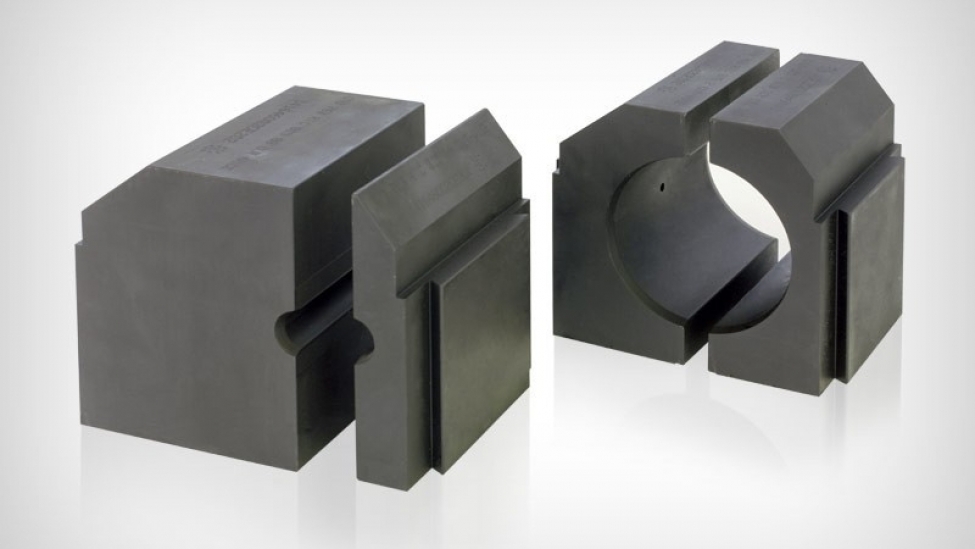

NICKEL PLATING

PROCESS: Electrolytic nickel plating is a galvanic treatment that can be performed exclusively on a metallic material. The nickel layer can be decorative, anti-corrosion and wear-resistant. It is also used as a binder for the deposition of carbides, diamonds and boron.

THICKNESS: the process allows the deposition of thick nickel, up to a maximum of 3 tenths of a millimeter

CAPACITY:

THICKNESS: the process allows the deposition of thick nickel, up to a maximum of 3 tenths of a millimeter

CAPACITY:

- Maximum cylinder diameter: 600 mm

- Maximum length: 500mm

- Maximum weight: 500kg

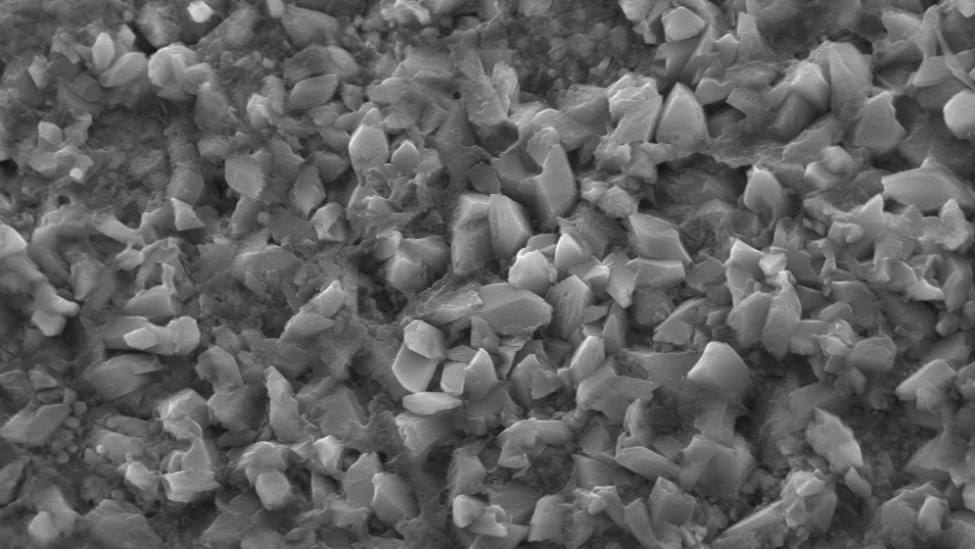

PHOSPHATING

PROCESS: Galvanic process to increase the corrosion resistance and anti-friction property, for general components, replacing the traditional paint.TREATABLE MATERIALS: Ferrous materials and low alloy steels

THICKNESS: 5-10 micron

CAPACITY:

- Max Cylinder diameter: 500 mm

- Max Length: 700 mm

- Max Weight: 500 kg

| Treatments | Materials | Thickness | Density | Corrosion res. (salt mist spray test ASTM B117) | Color |

|---|---|---|---|---|---|

| Mn Phosphating | Structural and Construction Steel, Low alloy Steel, Cast Iron | 0,002 to 0,010 mm | 7,7 g/m2 | 72 hours | Black |

| Nickel Plating | Structural and Construction Steel, Low alloy Steel, Cast Iron | 0,01 to 0,3mm | 4,5 g/dm2 | 96 hours | Grey |

Download Data Sheet

| PHOSPHATING TREATMENT | |

| EUROLLS COATING CATALOG |