ANTIWEAR COATING USING MIG WELD TECHNOLOGY

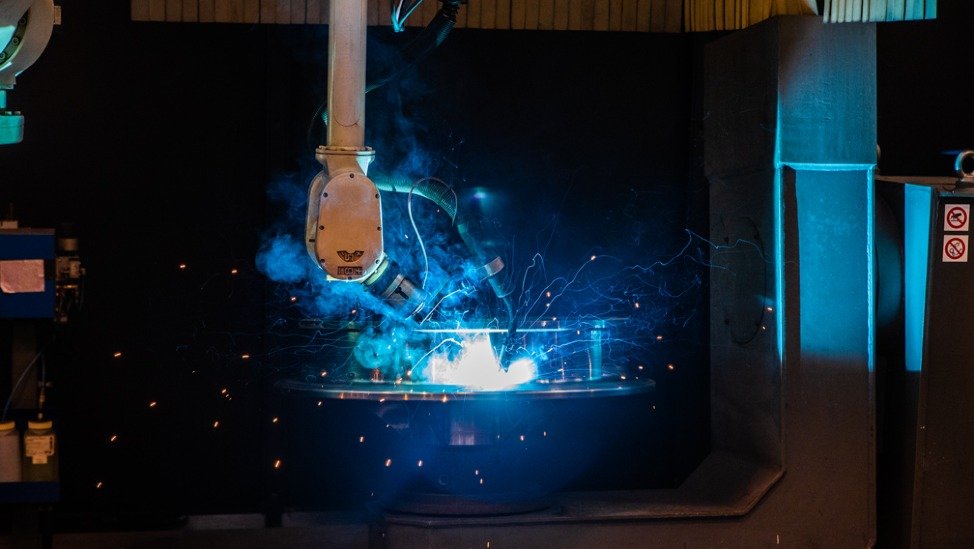

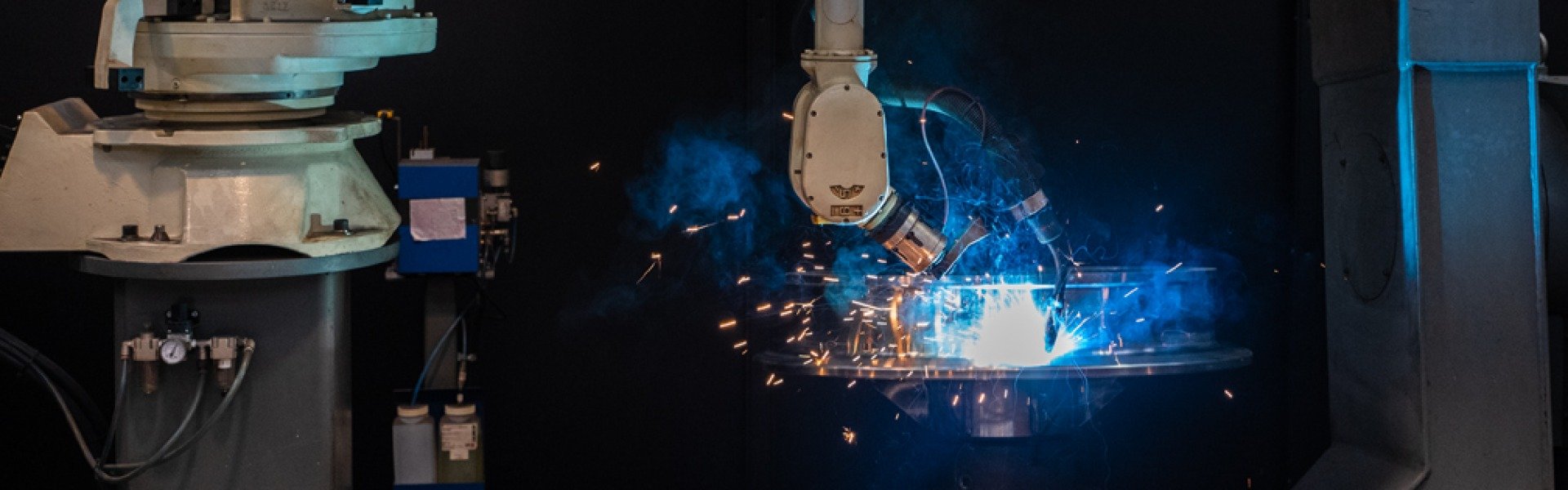

This welding system which is integrated into an anthropomorphic robot, allows the application of a thick coating, for cold and hot applications, suitable to repair parts subject to wear, such as tools for the steel industry, rolling parts and earth movement devices.

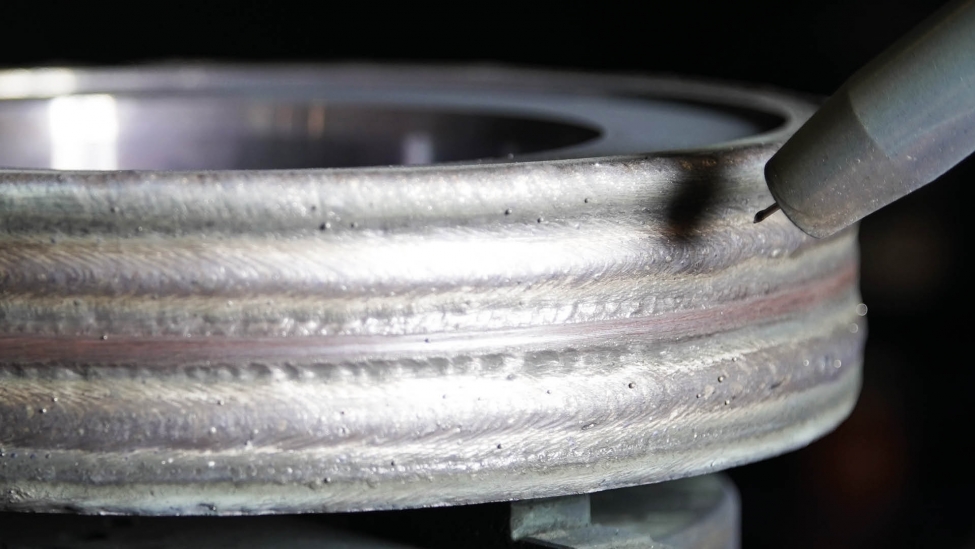

PROCESS: High thickness coatings of hard materials which are deposited with MIG welding technology (with an anthropomorphic robot).

MAIN APPLICATION: anti-wear, regeneration of worn surfaces.

MAIN PRODUCTS: Capstans and pulleys for the wire sector, rolls for metal sheets, cutting tools.

CAPACITY: Up to 1.000mm on diameter, 1.500mm length.

HIGHLIGHTS: Very high thickness layer (up to 10mm).

PROCESS: High thickness coatings of hard materials which are deposited with MIG welding technology (with an anthropomorphic robot).

MAIN APPLICATION: anti-wear, regeneration of worn surfaces.

MAIN PRODUCTS: Capstans and pulleys for the wire sector, rolls for metal sheets, cutting tools.

CAPACITY: Up to 1.000mm on diameter, 1.500mm length.

HIGHLIGHTS: Very high thickness layer (up to 10mm).

| Eurolls commercial designation | Material | Colour | Hardness | Thickness | Max working temperature | Roughness | Coating technology | Substrate | Property | Application |

| EU_WELD_LASTIFIL 600 | lastifil 600 | grey | 58-62 Hrc | 5-10mm | 500°C | 0,4-0,8 Ra | welding | steel | chromium alloy with medium wear resistance up to 500°C | knives for cold cutting, pulley for wire, deburring molds, mills, buldozzers, hammers, conveyance wheels |

| EU_WELD_STELLITE | stellite grade 6 | grey | 38-42 Hrc | 5-10mm | 900°C | 0,4-0,8 Ra | welding | steel | cobalt alloy, with very high corrosion resistance, high hardness resistance at high temperature | alloy resistant to corrosion and abrasion, resistant to stresses from impacts and extreme thermal shocks. used in cylinders and valves, hot lamination equipment, shear blades. resistance to abrasion, corrosion, cavitation at high temperatures |

Download Data Sheet

| WELDING COATING | |

| EUROLLS COATING CATALOG |