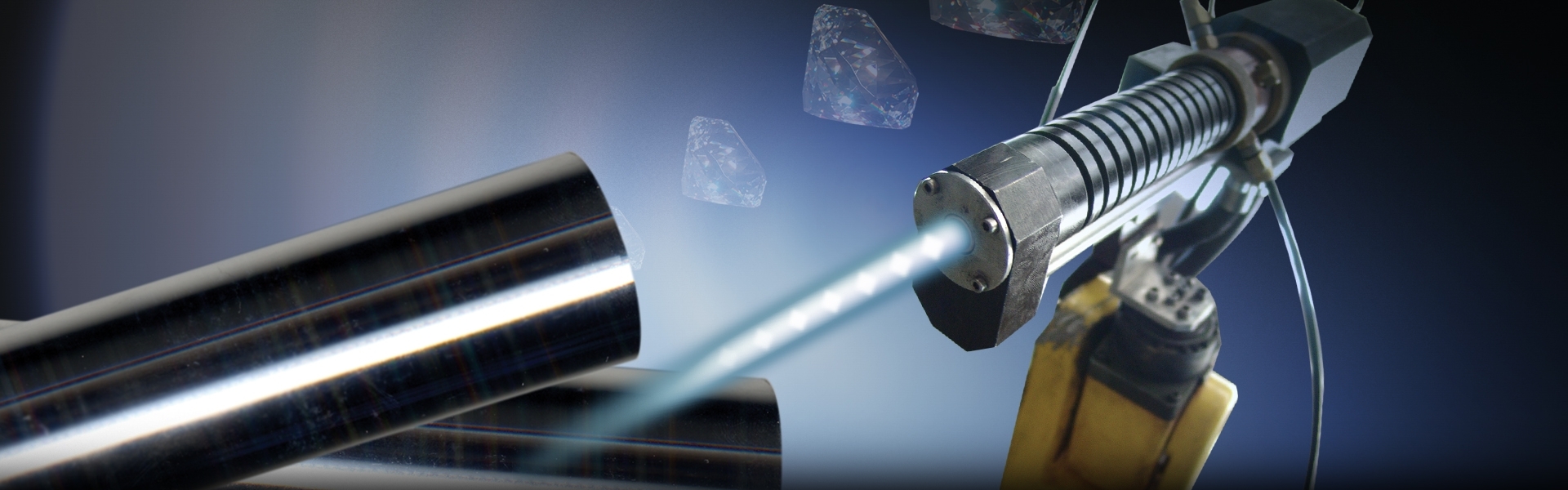

SPECIAL COATING USING PLASMA SPRAY / HVOF TECHNOLOGIES

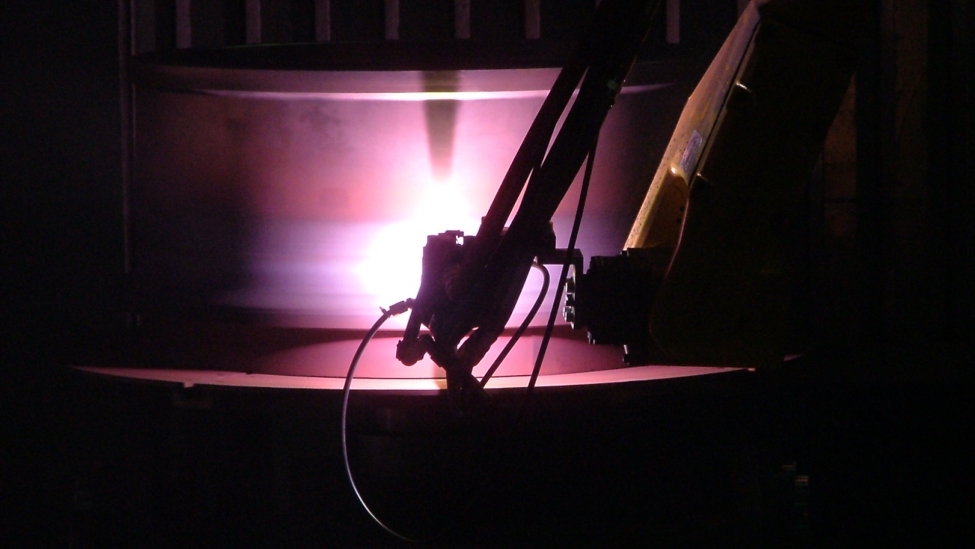

Eurolls can also offer ceramic and carbide coating applications with a thermal spray process used in a hybrid system.

PROCESS: Medium thickness coatings of hard materials, melted and sprayed onto a surface.

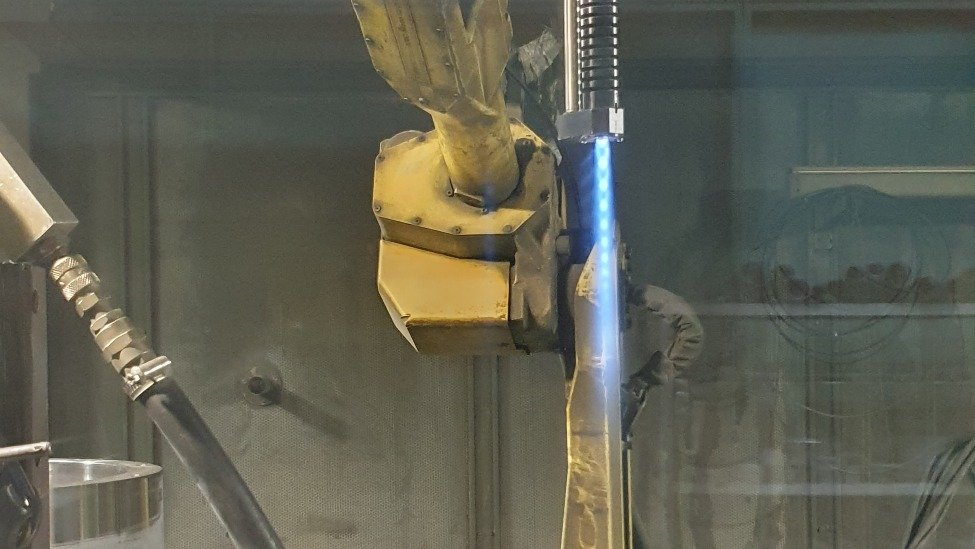

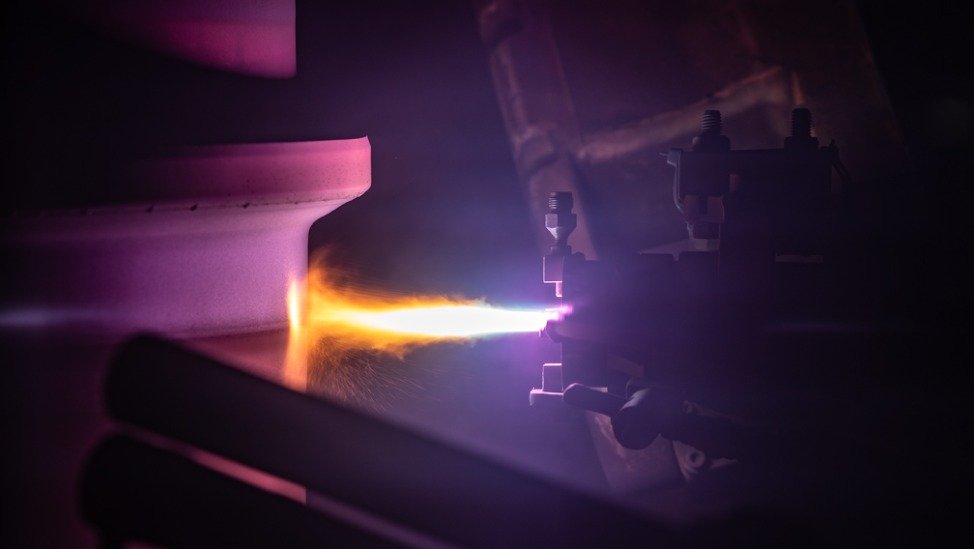

Two different spraying guns can be used:

PROCESS: Medium thickness coatings of hard materials, melted and sprayed onto a surface.

Two different spraying guns can be used:

- APS (Air Plasma Spray): used to deposit ceramic coatings

- HVOF (High Velocity Oxygen Fuel): used to deposit carbide coatings

MAIN APPLICATION: Anti-wear, anti-corrosion, thermal and electrical insulation

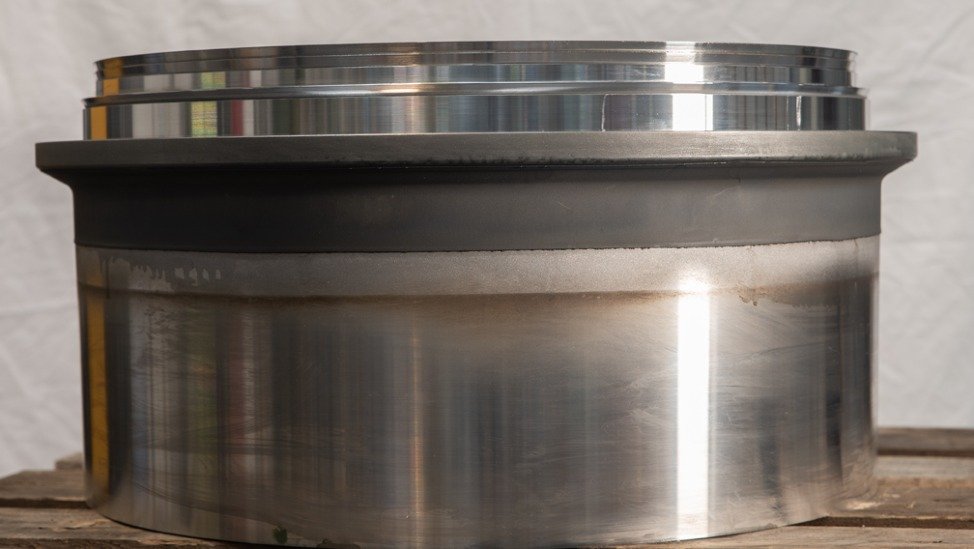

MAIN PRODUCTS: Capstans and pulleys for the wire sector, rolls for metal sheets forming, cutting tools, etc.

CAPACITY:

MAIN PRODUCTS: Capstans and pulleys for the wire sector, rolls for metal sheets forming, cutting tools, etc.

CAPACITY:

- Max extension flat surface: 1.600x6.000 mm

- Max Cylinder diameter: 1.600 mm

- Max Length: 6.000 mm

- Max Weight: 6.000 kg

HIGHLIGHTS: Medium thickness coating (a few tenths of a millimeter). Low temperature process (the piece never exceeds 100°C).

| Eurolls commercial designation | Material | Colour | Hardness | Thickness | Max working temperature | Roughness | Coating technology | Substrate | Property | Application |

| EU_ALUOXIDE | Aluminium Oxide | white | 1100 Hv | 0,05-0,40mm | 1650°C | 6-0,6 Ra | thermal spray | steel | good wear and oxidation and chemical resistance | suitable for insulating coatings due to high dielectric stiffness, resistant to high temperatures, used for rotating seals, wire guide, electronic field applications |

| EU_ALUTITANIUMOXIDE | Aluminium Titanium Oxide | black-blue | 1000 Hv | 0,05-0,40mm | 550°C | 5-0,4 Ra | thermal spray | steel | good wear resistance, good toughness and good oxidation resistance up to 550°C. good sliding wear | textile fiber industry, in which it is required surface resistance and resistance in acid and alkaline environments, is less fragile than Al2O3 and less resistant to chemical attacks |

| EU_CHROMEOXIDE | Chromium Oxide | black | 1300 Hv | 0,10-0,40mm | 540°C | 5-0,4 Ra | thermal spray | steel | good wear and corrosion resistance | resistance to wear from abrasive grains, erosion from particles, cavitation. used for corrosion-resistant anti-wear coatings used in the pump gasket areas, rolls, rings with wear (synthetic materials) - does not resist to chlorinated compounds. |

| EU_BRONZE | Bronze | orange | 300 Hv | 0,10-4mm | 500°C | 12-0,6 Ra | thermal spray | steel | low hardness coating with good lubricant property, high toughness, coating up to 5mm thickness | main application is the bronzing function in replacement of traditional application due to very god lubricant property (bearings, lardons, guides, pistons for compressors, pads) |

| EU_MOLYBDENUM | Molybdenum | black | 300 Hv | 0,10-0,40mm | 340°C | 5-0,4Ra | thermal spray | steel | antyfriction coating with low frictional characterics | pistons, fuel injectors, ingot molds, furnace components and metlting electrodes, valve and pump component, gears ,fretting or sliding wear components. resistance to molten metals whn used in non oxidizing atmospheres |

| EU_TUNGSTENCARBIDE | Tungsten Carbide | grey | 1450 Hv | 0,03-0,50mm | 500°C | 4-0,02 Ra | thermal spray | steel | high wear resistance, low corrosion resistance | very good wear resistance, to be avoided in corrosive solutions |

| EU_WCCRCARBIDE | Tungsten Chromium Carbide | grey | 1350 Hv | 0,03-0,50mm | 500°C | 4-0,02 Ra | thermal spray | steel | good abrasion wear resistance. good resistance at oxidation at high temperature. respect to wc-co coating, possible use in water solution | it is different from the WC-CO whit more fine grain sizes, characteristics comparable with good erosion resistance from particles, can be used in water solutions with appropriate basic material (inox) |

| EU_CHROMECARBIDE | Chromium Carbide | silver grey | 1100 Hv | 0,03-0,40mm | 870 °C | 4-0,1 Ra | thermal spray | steel | good abrasion wear resistance. good resistance at oxidation at high temperature | principally used for gas turbine nozzles, exhaust valves, seal rings, high temperature anti-wear applications, elastic bands, excellent resistance to chemical attack in a particularly aggressive environment, excellent corrosion resistance in the saline environment |

Download Data Sheet

| THERMALSPRAY COATINGS | |

| EUROLLS COATING CATALOG |